Mechanical and pneumatic control systems

How mechanical control systems work and types of motion

Mechanical control systemsuse parts for movement/force control. They include input, process, and output. Types of motion: linear, rotary, reciprocating, oscillating.

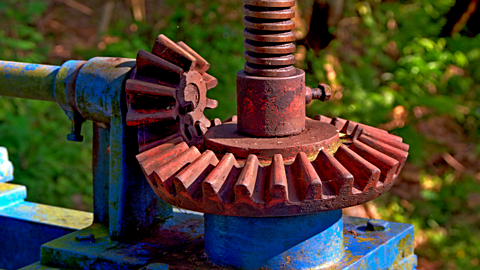

How do different gears transmit motion?

Gears transmit motion and force in machines, with types like spur, bevel, worm and wormwheel, rack and pinion, meshed gears, and threaded bars.

How pulley and transmission systems work

Pulley systems ease lifting. Single pulleys change force direction; fixed pulleys change direction; movable pulleys reduce effort. Adding pulleys creates mechanical advantage.

What is 'conversion of motion'?

Cams convert rotary to reciprocating motion.

What are levers and linkages?

Levers use mechanical advantage to ease lifting; they are a bar and a pivot (fulcrum) with effort, fulcrum, and load arranged differently in first, second, and third class levers

What are pneumatic principles?

Pneumatics uses compressed air to power machines, providing a clean, efficient, and safe method for various applications.

How robots are used and controlled

Robots are used in industry, healthcare, space, homes, and agriculture to boost efficiency, enhance safety, and reduce costs, controlled with actuators and sensors