Key points

- Manufacture a prototype that meets your design specifications.

- Choose a range of appropriate materials.

- Demonstrate manufacturing skills and attention to detail.

- Test your prototype and write a reflective evaluation of its effectiveness.

- Evaluate your prototype against your specification.

- Suggest how to modify or improve the prototype.

This section is relevant for students embarking on their design and manufacturing project and who are pursuing either Option A: Electronic and Microelectronic Control Systems; or Option B: Mechanical and Pneumatic Control Systems. Typically referred to as the Systems pathway.

Manufacturing your design

Manufacture involves creating a prototype of your design that meets all the specifications you set earlier. You will need to choose the right materials that suit your product, whether it is something sturdy, lightweight or easy to work with. When building your prototype it is important to show off your manufacturing skills, paying attention to accuracy, quality and finish. This part of the project shows your ability to turn your design ideas into a real, functional product while maintaining high standards.

When building your prototype, you'll have access to a wide range of tools and machinery in the school workshop. Machines like the pillar drill, band facer, polisher, milling machine, and centre lathe will be useful, along with the full range of hand tools. You might also have access to more advanced equipment like CNC milling machines, laser cutters, and 3D printers.

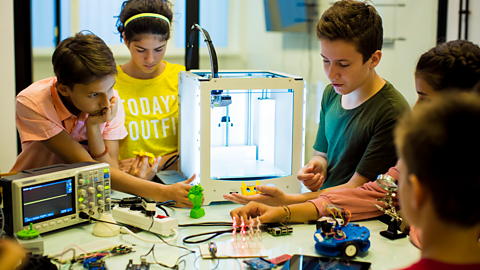

Image caption, Students using a 3D printer

Image caption, A bandfacer in school workshop

Image caption, Student being shown how to use a lathe

Image caption, A pillar drill

Image caption, Teacher showing students how to use a wood chisel

1 of 5

How to evaluate your work

Evaluation is about testing your prototype to see if it works as expected. Once you have tested it, you need to reflect on how effective it is by comparing it to the specifications you created at the start. Does it meet all the requirements? Think about what works well and what does not. Finally, suggest ways to improve or modify your prototype, whether that is changing materials, design features or functionality to make it better.

- Test your prototype and write a reflective evaluation of its effectiveness.

- Evaluate your prototype against your specification.

- Suggest how to modify or improve the prototype.

Evaluation is part of the iterative design process, a circular design process that models, evaluates and improves designs based on the results of testing.

The iterative design process works by analysing the feedback received and evaluating against the specification criteria to determine the effectiveness of the product and consequently to redevelop the product. Further improvements can be made and then more feedback can be gathered until both the client and the target market are happy with the outcome.

Without the iterative cycle of evaluation and improvement from both the client and the target market, the product may not be the best on the market. This will allow another manufacturer to produce a better product that will be more successful.

You must complete:

- Testing in situ

- Evaluation against the original design specification

- Future modifications

Test yourself

Further study

Manufacturing practices. revision-guideManufacturing practices

Brush up on manufacturing and planning

What is the design process? revision-guideWhat is the design process?

Find out more about the design process.

More on Product design pathway

Find out more by working through a topic